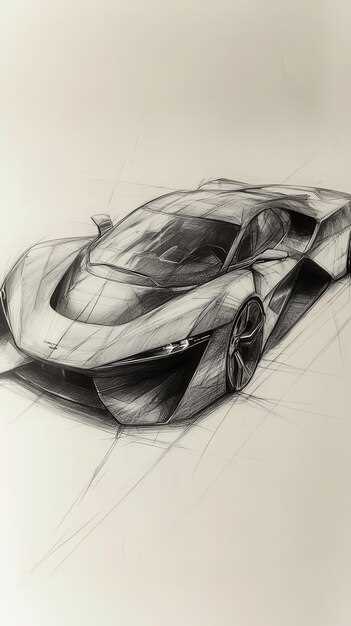

The journey from concept sketches to real cars is a fascinating tale of innovation and creativity. It begins with the humble act of sketching, where automotive designers translate their ideas onto paper. Each line and curve represents not just a shape, but a vision for a future vehicle that can inspire, thrill, and perform. In this stage, imagination knows no bounds, allowing designers to explore various styles and functionalities that could revolutionize the automobile industry.

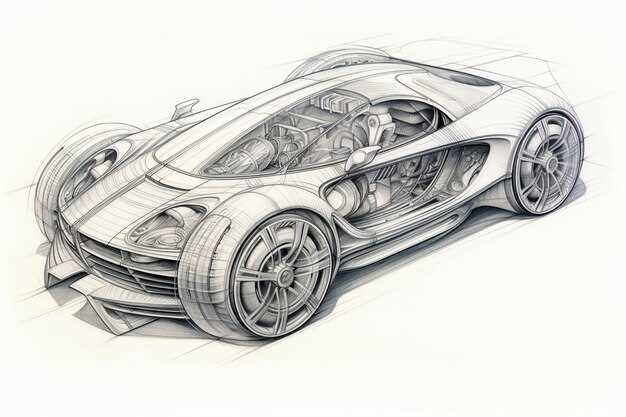

As sketches evolve, the process shifts from artistry to engineering. These initial drawings must undergo rigorous refinement, transforming aesthetic concepts into tangible blueprints that will guide manufacturing. This phase involves collaboration among various professionals, including engineers, marketers, and production specialists, who work together to ensure that the car not only looks good but also meets safety and performance standards.

Finally, the culmination of this meticulous process results in the creation of a real car, a testament to the hard work and dedication of everyone involved. What began as a simple sketch has now transformed into a fully realized vehicle, ready to take to the road. This journey illustrates not only the creativity involved in automotive design but also the technical expertise required to bring those creations to life.

From Concept Sketches to Real Cars: Crafting the Journey

The journey from concept sketches to real cars is a fascinating blend of creativity, engineering, and innovation. It begins with the initial idea, where designers translate abstract thoughts into tangible images through sketching. These concept sketches serve as the foundation, visualizing the car’s style, functionality, and features.

Once a concept sketch receives approval, it transitions to the digital realm. Advanced software allows designers to refine their ideas, focusing on proportions, curves, and ergonomics. This phase emphasizes collaboration, as engineers and designers work together to ensure the feasibility of the concept while maintaining its artistic vision.

The development of prototype models follows, where 3D printing and CNC machining bring the sketches to life. These prototypes undergo rigorous testing, examining performance, safety, and drivability. Feedback from these tests is crucial, prompting revisions to the original designs, ensuring that the final product aligns with market demands and regulatory standards.

As prototypes evolve into pre-production models, focus shifts towards refining details such as materials, interior design, and technology integration. The aspect of user experience becomes central, as the car must resonate with potential buyers. Market research plays a significant role in shaping the final adjustments.

Ultimately, when the production phase begins, the concept sketch has undergone a remarkable transformation. It has been meticulously crafted, tested, and refined, turning an imaginative vision into a tangible vehicle. This process not only highlights the importance of concept sketches but also illustrates the collaborative spirit that drives the automotive industry forward.

Techniques for Creating Engaging Concept Sketches

Creating engaging concept sketches for cars involves a combination of artistic skill and technical understanding. The goal is to communicate the essence of a vehicle while capturing its unique design features. To achieve this, several techniques can enhance the sketching process.

First, understand the fundamentals of perspective. Applying proper perspective helps in accurately depicting the proportions and scale of the car. Using vanishing points and horizon lines can create depth, making the sketch more lifelike. Practice drawing simple shapes in perspective before tackling complex car designs.

Next, focus on silhouette. A strong silhouette can make the car instantly recognizable. Emphasize the vehicle’s overall shape by simplifying the design elements. Use bold lines to outline the major features, which helps convey the car’s character quickly.

Gesture drawing is another effective technique. This quick way of sketching focuses on capturing the movement and flow of the car, allowing designers to explore different forms rapidly. Spend time on warm-up sketches, which enable natural hand movements and foster spontaneous ideas.

Incorporate details gradually. Start with broad forms and progressively add elements such as headlights, grilles, and interior designs. This layered approach allows for adjustments and refinements without overwhelming the initial concept. Each detail should serve to enhance the narrative of the design.

Color can also play a significant role in the engagement level of sketches. Even if you start with black and white, consider adding color washes digitally or with traditional media to highlight specific areas. Color choices can convey emotions and intentions, influencing how viewers perceive the design.

Lastly, encourage feedback from peers or potential users. Sharing sketches with others can provide fresh perspectives and insights that can enhance the design. Constructive criticism is invaluable in refining concepts and discovering new directions that may not have been considered initially.

Turning Ideas into Prototypes: The Design Development Process

Transforming a concept car idea into a tangible prototype involves a meticulous design development process. This journey is essential for ensuring that innovative designs meet both aesthetic and functional requirements.

The following key stages outline the design development process:

-

Initial Conceptualization: This stage begins with brainstorming sessions where designers explore various themes, styles, and technologies. Sketches and digital renderings are created to visualize the concepts.

-

Research and Feasibility: After selecting promising concepts, thorough research is conducted to assess feasibility. This includes market analysis, target audience considerations, and regulatory compliance.

-

Design Iteration: Designers refine sketches and develop 3D models. They collaborate with engineers to ensure that the design aligns with manufacturing processes and performance goals.

-

Prototype Development: A physical prototype is created through techniques such as 3D printing or clay modeling. This prototype serves to test the design in terms of ergonomics, aesthetics, and functionality.

-

Testing and Evaluation: The prototype undergoes various tests, including aerodynamic assessments and crash simulations. Feedback is collected to inform necessary adjustments.

-

Final Adjustments: Based on testing results, final modifications are made. This may involve altering materials, dimensions, or design elements to optimize performance and aesthetics.

-

Preparation for Production: Once the prototype meets all criteria, the design is finalized for mass production. Detailed specifications and manufacturing guidelines are prepared.

This structured pathway from concept sketch to prototype not only enhances the likelihood of successful car production but also fosters innovation and creativity in automotive design. Each stage plays a critical role in realizing the vision behind the concept, ensuring that the final vehicle resonates with consumers while adhering to industry standards.

Testing and Refining: The Transition from Concept to Production Model

The journey from concept sketches to final production models is a complex process that involves rigorous testing and refining. Initially, designers create sketches to visualize their ideas, focusing on aesthetics, functionality, and market appeal. However, these early concepts are just the beginning of a longer journey.

Once a sketch is approved, engineers and designers collaborate to develop a working prototype. This prototype undergoes extensive testing to evaluate performance, safety, and manufacturability. Every element, from the engine mechanics to body materials, is scrutinized under various conditions. Feedback is gathered and analyzed, leading to necessary adjustments in the design.

The refinement process is iterative. Each round of testing can reveal unforeseen issues, prompting further modifications to the original concept. For instance, aerodynamics may not meet expectations, leading to changes in the vehicle’s shape or materials. Likewise, user feedback may inspire alterations in the interior layout or feature set, ensuring that the production model resonates with consumers.

Another critical aspect of this transition is compliance with regulatory standards. Every market has specific safety and environmental regulations that the final vehicle must adhere to. The concept’s design must be adaptable, allowing changes that ensure compliance without sacrificing the original vision.

Ultimately, the transition from concept to production model is a meticulous process that balances creativity with technical precision. The goal is to create a car that not only looks stunning but also performs reliably and meets the needs of its intended audience.