When it comes to selecting the right material for your projects, fiberglass and carbon fiber are two prominent options that often come into play. Both materials possess unique properties that cater to various requirements, making them suitable for a wide array of applications from automotive to aerospace. Understanding the differences between these two types of fiber composites is essential for making an informed decision.

Fiberglass, composed of fine strands of glass, has been a staple in the manufacturing industry for decades. Its advantages lie in its cost-effectiveness, ease of molding, and sufficient strength for many applications. However, it also has limitations concerning weight and stiffness compared to its counterpart.

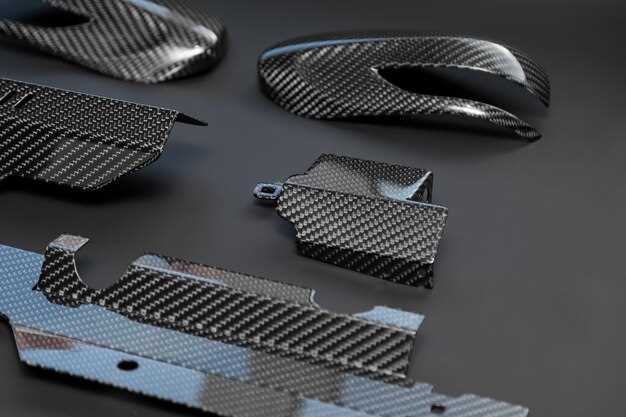

On the other hand, carbon fiber is renowned for its exceptional strength-to-weight ratio. This material is increasingly favored in high-performance applications due to its lightweight nature and rigidity. However, it comes at a higher price point and can be more challenging to work with. Understanding these nuances allows you to weigh the pros and cons effectively, ensuring you choose the best kit tailored to your specific needs.

Cost Analysis: Is Fiberglass More Budget-Friendly Than Carbon Fiber?

The cost of materials significantly impacts decision-making when selecting between fiberglass and carbon fiber kits. Generally, fiberglass is more budget-friendly than carbon fiber. The production process for fiberglass is less complicated and requires less expensive raw materials, which contributes to its lower overall price. In many instances, fiberglass kits can be acquired for a fraction of the price of equivalent carbon fiber options.

Carbon fiber, known for its strength-to-weight ratio, often comes with a higher price tag. The advanced manufacturing techniques required to create carbon fiber components not only add to the material cost but also increase labor expenses. As a result, while carbon fiber offers performance benefits, the initial investment can be a significant factor for budget-conscious consumers.

When evaluating which material to choose, it is essential to consider not just the purchase price but also long-term costs. Such factors can include maintenance, durability, and any potential repairs. Fiberglass may require more frequent repairs and maintenance due to its lower impact resistance compared to carbon fiber. Thus, although the upfront costs for fiberglass are lower, the lifecycle costs might even out or lean in favor of carbon fiber over time.

In summary, fiberglass is generally the more budget-friendly option for those looking to minimize initial costs. However, for users needing high performance and durability, the investment in carbon fiber can prove worthwhile despite the higher initial price.

Weight and Strength: How Do Fiberglass and Carbon Fiber Compare in Performance?

When assessing the performance of materials for various applications, weight and strength are critical factors. Both fiberglass and carbon fiber offer unique advantages and drawbacks related to these aspects.

Weight:

- Carbon fiber is significantly lighter than fiberglass, making it an ideal choice for applications where weight savings are crucial.

- Fiberglass, while heavier, can still be a suitable option depending on the specific use-case and desired strength characteristics.

Strength:

- Carbon fiber boasts a higher tensile strength compared to fiberglass, providing superior resistance to deformation under stress.

- Fiberglass offers decent strength but lacks the same rigidity and stability, which can lead to more significant flexing or bending in high-stress situations.

In terms of performance, the choice between fiberglass and carbon fiber largely depends on the specific requirements of the project. For applications needing lightweight and high strength, carbon fiber is typically the preferred option. However, for projects that can accommodate additional weight while still requiring a fair level of strength and durability, fiberglass remains a viable and often more cost-effective solution.

Durability and Maintenance: Which Material Requires Less Attention Over Time?

When comparing fiberglass and carbon fiber kits, durability and maintenance are crucial factors that influence long-term ownership satisfaction. Fiberglass is known for its good resistance to environmental factors, including moisture and UV radiation, which helps prevent degradation over time. This material is relatively tough, but it can be prone to cracks and scratches if subjected to significant impact. Regular maintenance involves inspecting for any signs of wear and applying protective coatings to prolong its lifespan.

On the other hand, carbon fiber stands out for its superior strength-to-weight ratio, making it less likely to suffer from damage in the first place. This material is more resistant to the fatigue that often results from repetitive stress and typically outlasts fiberglass in demanding applications. Carbon fiber does not require as much maintenance because it is less susceptible to corrosion and environmental damage, making it a more hassle-free option for users who need something that performs well over time.

In summary, both fiberglass and carbon fiber have their unique advantages in terms of durability. However, if minimal maintenance and long-term performance are priorities, carbon fiber kits generally require less attention over time compared to their fiberglass counterparts. Understanding these differences can help users make informed decisions about which material best suited their needs.